|

|

|

|

|

Ulsan, South Korea, July 22, 2013 - (ACN Newswire) - Considerable improvement in device performance of polymer-based optoelectronic devices is reported today by researchers from Ulsan National Institute of Science and Technology (UNIST), South Korea. The new plasmonic material, can be applied to both polymer light-emitting diodes (PLEDs) and polymer solar cells (PSCs), with world-record high performance, through a simple and cheap process.

| | UNIST: Two In One Solution for Low Cost Polymer LEDs and Solar Cells |

The contrary demands of these devices mean that there are few metal nanoparticles that can enhance performance in PLEDs and PSCs at the same time.

Most semiconducting optoelectronic devices (OEDs), including photodiodes, solar cells, light emitting diodes (LEDs), and semiconductor lasers, are based on inorganic materials. Examples include gallium nitride for light-emitting diodes and silicon for solar cells.

Due to the limited availability of raw materials and the complex processing required to manufacture OEDs based on inorganic materials, the cost of device fabrication is increasing. There is great interest in thin-film OEDs that are made from alternative semiconductors.

Among these materials, organic semiconductors have received much attention for use in next-generation OEDs because of the potential for low-cost and large-area fabrication using solution processing.

Despite extensive efforts to develop new materials and device architectures enhancing the performance of these devices, further improvements in efficiency are needed, before there can be widespread use and commercialization of these technologies.

The material prepared by the UNIST research team is easy to synthesize with basic equipment and has low-temperature solution processability. This low-temperature solution processability enables roll-to-roll mass production techniques and is suitable for printed electronic devices.

"Our work is significant also because it anticipates the realization of electrically driven laser devices by utilizing carbon dot*-supported silver nanoparticles (CD-Ag NPs) as plasmonic materials," says said Prof. Byeong-Su Kim. "The material allows significant radiative emission and additional light absorption, leading to remarkably enhanced current efficiency."

Surface Plasmon resonance is an electro-magnetic wave propagating along the surface of a thin metal layer and the collective oscillation of electrons in a solid or liquid stimulated by incident light. SPR is the basis of many standard tools for measuring adsorption of materials onto planar metal (typically gold and silver) surfaces or onto the surface of metal nanoparticles.

The team demonstrated efficient PLEDs and PSCs using surface Plasmon resonance enhancement with CD-Ag NPs. The PLEDs achieved a remarkably high current efficiency (from 11.65 to 27.16 cd A-1) and luminous efficiency (LE) (from 6.33 to 18.54 lm W-1).

PSCs produced in this way showed enhanced power conversion efficiency (PCE) (from 7.53 to 8.31%) and internal quantum efficiency (IQE) (from 91 to 99% at 460 nm). The LE (18.54 lm W-1) and IQE (99%) are among the highest values reported to date in fluorescent PLEDs and PSCs, respectively.

"These significant improvements in device efficiency demonstrate that surface Plasmon resonance materials constitute a versatile and effective route for achieving high performance polymer LEDs and polymer solar cells," said Prof. Jin Young Kim. "This approach shows promise as a route for the realization of electrically driven polymer lasers."

The fellow researchers include Hyosung Choi, Seo-Jin Ko, Yuri Choi, Taehyo Kim, Boram Lee, and Prof. Myung Hoon Song from UNIST, and researchers from Chungnam National University, Pusan National University, and Gwangju Institute of Science and Technology.

This research was supported by a WCU (World Class University) program through the Korea Science and Engineering Foundation funded by the Ministry of Education, Science and Technology, the National Research Foundation of Korea Grant, the Korea Healthcare technology R&D Project, the Ministry of Health & Welfare, Korea and the International Cooperation of the Korea Institute of Energy Technology Evaluation and Planning (KETEP) grant funded by the Korean government Ministry of Knowledge Economy.

* Carbon-dot: Carbon dots (CDs) consist of carbon, hydrogen, and oxygen with a quasi-spherical structure in which the carbon shows the character of crystalline graphite.

IMAGE CAPTIONS:

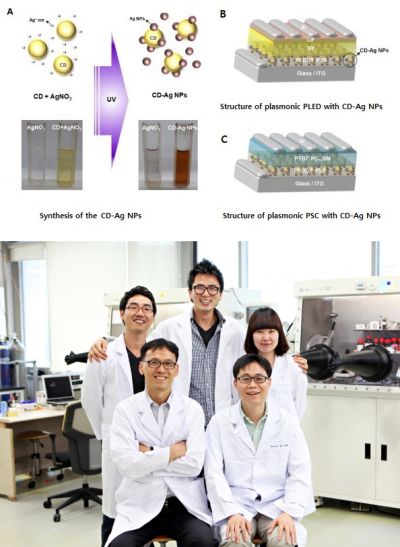

Image 1: Synthesis of the CD-Ag NPs and the structures of plasmonic PLED/PSC with CD-Ag NPs

Image 2: The Research Group of Prof. Jin Young Kim (front left) and Prof. Byeong-Su Kim (front right)

REFERENCES:

Research paper: "Versatile surface plasmon resonance of carbon dot-supported silver nanoparticles in polymer optoelectronic devices" Nature Photonics DOI: 10.1038/nphoton.2013.181

Ulsan National Institute of Science and Technology - www.unist.ac.kr

Homepage of Prof. Jin Young Kim - http://ngel.unist.ac.kr

Homepage of Prof. Byeong-Su Kim - http://bskim19.unist.ac.kr

Press release distributed by ResearchSEA on behalf of Ulsan National Institute of Science and Technology (UNIST).

Topic: Research and development

Source: Ulsan National Institute of Science and Technology (UNIST)

Sectors: Electronics, Science & Research

https://www.acnnewswire.com

From the Asia Corporate News Network

Copyright © 2026 ACN Newswire. All rights reserved. A division of Asia Corporate News Network.

|

|

|

|

|

|

|

|