5N+ Purity and On-Spec EBC Confirm Lac Knife's Potential as a North American Source of Ultra-High-Performance Graphite Applications

Ottawa, Ontario--(ACN Newswire - December 11, 2025) - Focus Graphite Inc. (TSXV: FMS) (OTCQB: FCSMF) (FSE: FKC0) ("Focus" or the "Company") a Canadian developer of high-grade flake graphite deposits and innovator of next-generation battery technology, is pleased to announce that follow-on purification and elemental analysis of material from its Lac Knife deposit (concentrate Lot ID: GN25073005) achieved 99.9996 wt.% ("5N+") and an Equivalent Boron Concentration ("EBC") of 2.03 ppm, confirming the material is within nuclear-grade specification and meets the technical thresholds required for several high-value advanced materials markets.

The test work, conducted using electrothermal purification with no halogen gases (e.g. chlorine) or acids, produced this ultra-pure result in two (2) hours, further validating a chemical-free, environmentally advantageous pathway compared to conventional purification methods. These results directly support Focus's ongoing engineering and scale-up programs funded under Natural Resources Canada's ("NRCan") Global Partnerships Initiative ("GPI"), under which the Company was awarded a non-repayable contribution of up to $14.1 million to accelerate North American capacity for clean, advanced material processing.

Subsequent elemental analysis calculated in accordance with ASTM C1233-15: Standard Practice for Determining Equivalent Boron Contents of Nuclear Materials yielded an Equivalent Boron Concentration ("EBC") of 2.03 ppm (Table 1), which falls below the critical 3 ppm threshold often cited for nuclear-grade graphite applications. The calculated EBC value is the most critical test of purity for nuclear industry use.

These results suggest that Lac Knife graphite has the potential to serve markets requiring ultra-high-purity large and jumbo flake natural graphite. Achieving both 5N+ purity and a high proportion of large-flake concentrate is uncommon in the natural graphite industry and may provide Focus with opportunities in markets historically reliant on synthetic graphite or otherwise inaccessible to peers. These findings are consistent with peer-reviewed research published in ACS Omega ("Ultrahigh Temperature Purification of Graphite for the Development of a Continuous Process," ACS Omega, 2025), conducted by American Energy Technologies Company ("AETC") and NRCan, which demonstrated that ultrahigh-temperature purification of natural Canadian graphite can produce materials exhibiting purity and crystallinity suitable for advanced applications. Focus's ongoing testwork indicates that residual impurities appear primarily on the surface of the graphite flake—as evidenced by ultra-fine features observed through scanning electron microscopy—suggesting that purification efficiency is strongly influenced by surface cleaning dynamics rather than structural defects within the carbon lattice.

Dean Hanisch, Chief Executive Officer of Focus commented, "These results validate Lac Knife as one of the rare unique natural graphite deposits capable of competing in high margin advanced technological markets and as a potential alternative to synthetic materials that are more expensive and have a larger environmental impact. With support from Canada's Federal Government, through Natural Resources Canada's Global Partnerships Initiative, we are now positioned to accelerate our scale-up work and unlock commercial pathways across nuclear energy, defense systems, graphene production, and next-generation electronics."

Lac Knife graphite's combination of ultra-high purity and large flake distribution positions it for a range of advanced industrial, clean energy, and high-technology applications.

Unlocking Advanced Markets Beyond Nuclear

Beyond nuclear applications, the ultra-high purity and medium-grain morphology of Lac Knife graphite position the material as a strategic feedstock for several advanced technology markets facing supply shortages, performance bottlenecks, and increasing scrutiny over material purity.

Graphene & Few-Layer Graphene (FLG) Production

In the graphene sector, precursor quality is the primary determinant of performance. Impurities commonly found in natural graphite—typically 0.5-1 microns in size, or roughly one thousand (1000) times thicker than a graphene layer—are known to disrupt electrical, thermal, and mechanical properties unless fully removed. Lac Knife's 5N+ purity eliminates these defects at the source, allowing the flake to exfoliate cleanly into high-value graphene structures.

Peer-reviewed research published in Carbon ("Influence of graphite geography on the yield of mechanically exfoliated few-layer graphene," Carbon, 2023) demonstrates the significance of geological origin in FLG production. In follow-on AETC—Yale University testing based on the methodologies outlined in that study, Lac Knife graphite achieved a record-high few-layer graphene yield of 22% ± 3%, outperforming all other natural samples evaluated and showing exfoliation behavior that synthetic graphite could not replicate.

Taken together, these results position Lac Knife as one of the few North American natural flake sources capable of supplying advanced graphene markets, including conductive coatings, EMI-shielding materials, flexible electronics, sensors, and next-generation energy storage systems.

Defence: IR Obscuration & Countermeasure Systems

The defence sector presents another major opportunity. Modern warfare increasingly requires materials capable of obscuring both visible and infrared signatures. Traditional obscurants—such as bronze flakes, titanium dioxide, and red phosphorus—pose toxicity, safety, and performance challenges. High-purity graphite and graphene derived from Lac Knife offer a lightweight, non-toxic, and thermally stable alternative capable of generating rapid-dispersion and longer-lasting obscurant clouds.

These materials are applicable to 40 mm muzzle-blast cartridges, airburst obscuration rounds for UAVs and rotorcraft, countermeasure dispenser systems, and naval surface-ship defence platforms. The U.S. Department of War currently procures graphene-based obscurants at approximately US$30,000 per ton, reflecting both strategic importance and limited supply. Lac Knife's purity is essential here, as impurities directly interfere with graphene formation and degrade obscurant performance.

Stealth Coatings & Electromagnetic Protection Systems

Ultra-high purity graphite also plays a critical role in stealth coatings and electromagnetic protection systems. Engineered systems operating across the 400 MHz to 30 GHz spectrum require materials that deliver highly reproducible electrical conductivity, thermal stability, and particle uniformity.

These coatings and composites are used in radar-absorbing structures for stealth UAVs, thermal-vision targeting systems, and a range of low-observable technologies. Because deviations in graphite purity can compromise system reliability or operator safety, defence and shielding markets pay substantial premiums—often up to US$50,000 per ton—for 5N-grade material. Lac Knife's combination of purity, consistency, and grain structure aligns closely with these stringent requirements and allows for further refinement into fine, superfine, ultrafine, or microfine grades without compromising integrity.

Critical Infrastructure Hardening (HEMP, IEMI and Geomagnetic Storms)

The same purity advantages extend into critical infrastructure protection. As governments and utilities work to harden electrical grids, substations, and 5G networks against high-altitude electromagnetic pulses (HEMP), intentional electromagnetic interference (IEMI), and severe geomagnetic storms, materials must perform reliably across high-frequency ranges and under extreme operating conditions.

Graphite-based shielding and coatings designed for these systems rely on predictable, reproducible material behavior—standards that only ultra-high purity graphite can meet. Lac Knife's 5N+ output offers the reliability required for these mission-critical applications.

Additional High-Value Markets Enabled by 5N+ Purity

In addition to these strategic sectors, Lac Knife's purity profile and particle characteristics also unlock potential in several high-value industries, including thermal management components for semiconductors and LEDs, high-pressure synthetic diamond production, PEM and SOFC fuel-cell bipolar plates, and laboratory-grade graphite consumables where contamination must be tightly controlled. In each of these markets, ultra-high purity reduces defects, increases stability, and improves overall system performance, enabling natural graphite to compete directly with synthetic alternatives.

Next Steps in Technical Validation

Focus is advancing a comprehensive technical qualification program to further define Lac Knife's suitability for nuclear and advanced material markets. Ongoing nuclear graphite testing includes detailed characterization of particle size distribution, compressibility, electrical resistivity, and coefficient of friction—parameters that determine whether a graphite material can perform reliably under the thermal, mechanical, and irradiation stresses present in high-temperature reactor environments. The Company expects to fabricate and evaluate near-net-shape graphite bricks, an essential step toward assessing Lac Knife material in full-scale core component geometries and within ASME Division 5 design criteria.

In parallel, Focus is extending its validation program—supported through NRCan's Global Partnerships Initiative ("GPI")—advanced materials markets. Current work programs under consideration include assessing Lac Knife graphite as a precursor for high-yield graphene, nano-wafer substrates, thin-film semiconductors, next-generation electronic components, and aerospace composites, including unmanned aerial systems (UAS). These sectors demand highly reproducible, ultra-high-purity carbon materials traditionally sourced from synthetic graphite. Early results indicate that Lac Knife's 5N+ natural graphite may offer a technically competitive—and potentially more sustainable—North American alternative to synthetic feedstocks across multiple high-value applications.

| Element |

Impurity Limit

(mg/kg) |

EBC Factor |

EBC Calculation |

| Ag |

0.05 |

0.0083 |

0.000415 |

| Al |

1 |

0.0001 |

0.0001 |

| B |

0.12 |

1 |

0.12 |

| Ca |

0.36 |

0.0002 |

0.000072 |

| Cd |

5 |

0.3172 |

1.586 |

| Cl |

1.5 |

0.0134 |

0.0201 |

| Co |

0.05 |

0.0089 |

0.00445 |

| Cr |

0.12 |

0.0008 |

0.000096 |

| Cu |

0.25 |

0.0008 |

0.0002 |

| Dy |

0.05 |

0.0818 |

0.00409 |

| Eu |

0.1 |

0.425 |

0.0425 |

| Fe |

0.21 |

0.0006 |

0.000126 |

| Gd |

0.05 |

4.3991 |

0.219955 |

| K |

0.6 |

0.0008 |

0.00048 |

| Li |

0.03 |

0.1439 |

0.004317 |

| Mn |

0.12 |

0.0034 |

0.000408 |

| Mo |

0.15 |

0.0004 |

0.00006 |

| Na |

0.085 |

0.0003 |

0.0000255 |

| Ni |

0.18 |

0.0011 |

0.00198 |

| S |

1.4 |

0.0002 |

0.00028 |

| Si |

1.46 |

0.0001 |

0.000146 |

| Sm |

0.05 |

0.5336 |

0.02668 |

| Th |

0.01 |

0.0005 |

0.000005 |

| Ti |

0.53 |

0.0018 |

0.000954 |

| U |

0.05 |

0.0005 |

0.000025 |

| V |

0.08 |

0.0014 |

0.000112 |

| |

|

|

|

| Total |

|

|

2.0277895 |

Table 1: EBC Calculation, Thermally Purified Lac Knife Lot ID: GN250730005

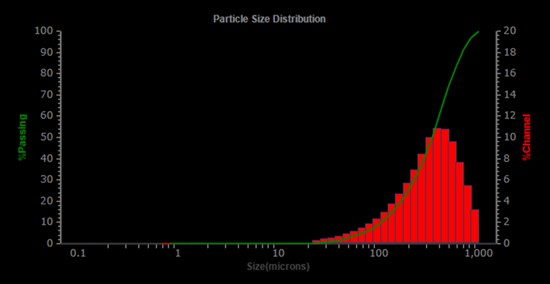

Figure 1: Particle Size Distribution, Thermally Purified Lac Knife Lot ID: GN250730005

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/1963/277711_279dc9a07490cbe0_001full.jpg

| Tap Density |

Scott Volume |

Surface Area |

LOI |

| |

|

|

|

| g/cc |

g/cc |

m2 /g |

Wt. % C |

| 0.6 |

0.4 |

1.4 |

99.9996 |

Table 2: Data, Thermally Purified Lac Knife Lot ID: GN250730005

| % Tile |

Size (um) |

| D10 |

105.2 |

| D50 |

337.3 |

| D90 |

673.8 |

| MV |

368.5 |

Table 3: Data (2), Thermally Purified Lac Knife Lot ID: GN250730005

Qualified Person

Dr. Joseph Doninger, Director of Technology and Manufacturing for Focus Graphite, is the Qualified Person ("QP") as defined under National Instrument 43-101 - Standards of Disclosure for Mineral Projects. Dr. Doninger has reviewed and approved the technical information contained in this news release. Dr. Doninger is a chemical engineer and the developer or co-developer of multiple U.S., European, and Canadian patents relating to carbon processing technologies and purification equipment. He has authored or co-authored more than two dozen technical papers and studies on graphite composite anodes, carbon-based materials for electrochemical energy storage systems, and advanced graphite for lithium-ion batteries.

About Focus Graphite Advanced Materials Inc.

Focus Graphite Advanced Materials is redefining the future of critical minerals with two 100% owned world-class graphite projects and cutting-edge battery technology. Our flagship Lac Knife project stands as one of the most advanced high-purity graphite deposits in North America, with a fully completed feasibility study. Lac Knife is set to become a key supplier for the battery, defense, and advanced materials industries.

Our Lac Tetepisca project further strengthens our portfolio, with the potential to be one of the largest and highest-purity and grade graphite deposits in North America. At Focus, we go beyond mining - we are pioneering environmentally sustainable processing solutions and innovative battery technologies, including our patent-pending silicon-enhanced spheroidized graphite, designed to enhance battery performance and efficiency.

Our commitment to innovation ensures a chemical-free, eco-friendly supply chain from mine to market. Collaboration is at the core of our vision. We actively partner with industry leaders, research institutions, and government agencies to accelerate the commercialization of next-generation graphite materials. As a North American company, we are dedicated to securing a resilient, locally sourced supply of critical minerals - reducing dependence on foreign-controlled markets and driving the transition to a sustainable future.

For more information on Focus Graphite Inc. please visit http://www.focusgraphite.com.

LinkedIn: https://www.linkedin.com/company/focus-graphite/

X: https://x.com/focusgraphite

Cautionary Note Regarding Forward-Looking Statements

Certain statements contained in this press release constitute forward-looking information. These statements relate to future events or future performance. The use of any of the words "could," "intend," "expect," "believe," "will," "projected," "estimated," and similar expressions, as well as statements relating to matters that are not historical facts, are intended to identify forward-looking information and are based on the Company's current beliefs or assumptions as to the outcome and timing of such future events.

In particular, this press release contains forward-looking information regarding, among other things, the anticipated performance and downstream applicability of ultra-high-purity graphite derived from the Lac Knife project; the potential for 5N+ purification results and nuclear-grade Equivalent Boron Concentration ("EBC") values to be replicated at larger scale; the implications of testwork conducted under Natural Resources Canada's Global Partnerships Initiative ("GPI") and the expected outcomes of related engineering, scale-up, and validation programs; the ability of Lac Knife graphite to meet nuclear, graphene, defense, electromagnetic shielding, thermal management, semiconductor, and other advanced material specifications; the potential commercial pathways associated with supplying high-purity natural graphite as an alternative to synthetic graphite; and the Company's strategy to position itself within North American supply chains for clean energy, advanced manufacturing, aerospace, and critical infrastructure markets.

Forward-looking statements are subject to known and unknown risks, uncertainties, and other factors that may cause actual results, performance, or achievements to differ materially from those expressed or implied by such statements. These risks and uncertainties include, but are not limited to, risks related to market conditions, regulatory approvals, changes in economic conditions, the ability to raise sufficient funds on acceptable terms or at all, operational risks associated with mineral exploration and development, and other risks detailed from time to time in the Company's public disclosure documents available under its profile on SEDAR+.

The forward-looking information contained in this release is made as of the date hereof, and the Company is not obligated to update or revise any forward-looking information, whether as a result of new information, future events, or otherwise, except as required by applicable securities laws. Because of the risks, uncertainties, and assumptions contained herein, investors should not place undue reliance on forward-looking information.

Neither TSX Venture Exchange nor its Regulation Services accepts responsibility for the adequacy or accuracy of this release.

To view the source version of this press release, please visit https://www.newsfilecorp.com/release/277711

Topic: Press release summary

Source: Focus Graphite Inc

Sectors: Metals & Mining

https://www.acnnewswire.com

From the Asia Corporate News Network

Copyright © 2025 ACN Newswire. All rights reserved. A division of Asia Corporate News Network.

|