|

|

|

|

|

Chigasaki, Japan, Mar 21, 2017 - (JCN Newswire) - ULVAC, Inc. is pleased to announce the NA-1500 dry etching system for 600mm advanced packaging substrates, providing for uniform Descum and Ti etching processes.

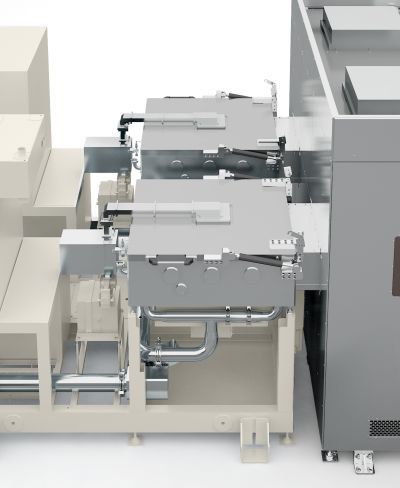

| | NA-1500 dry etching system |

| | NA-1500 process chamber |

Higher data transfer speeds require higher-density packaging technologies, while advanced mobile and wireless devices require thinner and higher-pin-count IC packages. Fan-Out Wafer Level Packaging (FO-WLP) is widespread, while Panel Level Packaging increases substrate size from 300mm to 600mm.

While there are many 200mm/300mm wafer dry etching systems in the market today, there was no dry etching system for 600mm substrates, providing for a uniform Descum process and Ti etching process. ULVAC developed the new system to address this need, and support mass-produced packaging processes.

The new NA-1500 dry etching system is made possible by enhancing our proven plasma source. Our plasma source enables fast, low-temperature etching in the resin layer, which had been previously impossible with existing CCP methods.

Our plasma source is also applicable to fluorine gases, so seed layer Ti etching, which requires a wet process, can proceed without side etching. SiO2 and SiN etching is available on the NA-1500 as well.

The NA-1500 dry etching system provides stable transfer and processes without abnormal discharge, ensuring warpage from the enlarged substrate is never an issue.

Applications:

1. Descum

2. Desmear

3. Surface treatment (Hydrophobicity <-> Hydrophilicity)

- Pretreatment for wet process such as plating, etc.

- Pretreatment for underfill

4. Resin material ashing

5. Seed layer Ti etching

6. SiO2/SiN etching

Images:

NA-1500 dry etching system -- http://bit.ly/2mTlx02

NA-1500 process chamber -- http://bit.ly/2nw2R4F

Notes:

1. Descum: Removal of residue (scum) in photolithography of photopolymer

2. CCP: Capacitive Coupling Plasma

3. Desmear: Removal of residue (smear) in Via formation with laser drill

Full Release with Process Performance (PDF) -- http://bit.ly/2nJgf4M

Our Future:

ULVAC has sold more than 200 dry etching systems since releasing our first 200mm wafer system 20 years ago. As electronic components become smaller and thinner, and higher-speed processing works on lower power in line with developments in IoT, manufacturing technologies for advanced packaging become more important. ULVAC supports this industry by providing systems that meet customer's future needs for flexible, invisible and wearable devices.

Contact:

Masahiro Harada

Corporate Sales & Marketing Division I

Advance Electronics Equipment Sales Dept.

ULVAC, Inc.

TEL: +81-467-89-2139 / FAX: +81-467-89-2254

https://www.ulvac.co.jp/

https://www.ulvac.co.jp/en/

https://www.ulvac.co.jp/products_e/

Topic: New Product

Source: ULVAC, Inc.

Sectors: Electronics, Materials & Nanotech, Engineering

https://www.acnnewswire.com

From the Asia Corporate News Network

Copyright © 2026 ACN Newswire. All rights reserved. A division of Asia Corporate News Network.

|

|

|

|

|

|

|

| |

| ULVAC, Inc. Related News |

|

| Thursday, 19 June 2025, 9:30 JST |

| ULVAC Continues Participation in "Lab-in-Fab" Project to Advance Piezoelectric MEMS Technology, Now Entering a New Phase |

|

| Thursday, 24 April 2025, 9:30 JST |

| ULVAC Develops Dilution Refrigerator for Quantum Computers |

|

| Friday, 21 March 2025, 10:30 JST |

| ULVAC Developing Next-Generation Dilution Refrigerator for Quantum Computing by 2026 |

|

| Thursday, 13 February 2025, 8:30 JST |

| ULVAC Develops Roll-to-Roll Lithium Deposition System, Unveiling at Battery Japan |

|

| Monday, 9 December 2024, 9:00 JST |

| Breaking Barriers in Data Communication: ULVAC & SAL join forces |

|

| More news >> |

|

|

|