|

| Tuesday, 27 November 2018, 20:30 JST | |

| |

|

|

|

|

| - Trials in polymer design processes can be cut to 1/40 by utilizing AI. |

TOKYO, Nov 27, 2018 - (JCN Newswire) - Showa Denko (SDK), National Institute of Advanced Industrial Science and Technology (AIST), and Research Association of High-Throughput Design and Development for Advanced Functional Materials (ADMAT) have found that the number of trials for the design of polymers with desired properties can be cut to about one-fortieth by utilizing artificial intelligence (AI).

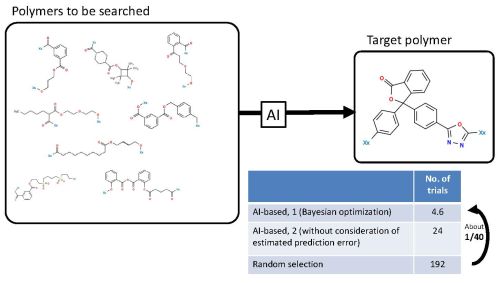

| | Figure 1: Concept of evaluation of number of trials for polymer design/verification |

| | Figure 2: Demonstration of high efficiency of AI-based polymer search |

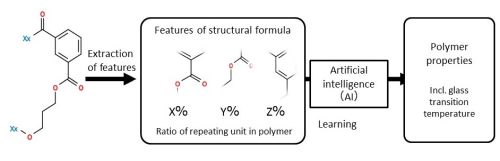

| | Figure 3: Building AI |

Researchers from SDK, AIST, and ADMAT conducted AI-based searches for polymers with desired properties, aiming to demonstrate the effectiveness of AI technology in the process of polymer design. As a model case, they focused on glass transition temperature, an index of heat resistance. Using 417 different types of structural data on polymers with known structures and glass transition temperatures, they conducted an AI-based search for a polymer with the highest glass transition temperature to see whether it is possible to shorten the development cycle.

First, randomly selected 10 sets of data were supplied as training data for AI. The Extended Connectivity Circular Fingerprints (ECFP) method was applied to the training data, digitizing structural features of polymers. Then, using Bayesian optimization*, the researchers made repeated efforts to predict and verify a polymer with the highest glass transition temperature out of the remaining 407 sets of data. Thus, they checked the number of trials required until the discovery of a target polymer. (Figure 1). To prevent the influence of the choice of data on the results, 500 examinations were conducted with different sets of initial training data, and the average number of trials was evaluated.

As a result, the researchers succeeded in discovering a target polymer with the highest glass transition temperature with an extremely small number of trials, namely, 4.6 times of trials on the average (Figure 2). This figure is about one-fortieth of the number of trials required under random selection of polymers, confirming the effectiveness of AI-based polymer design.

To build AI, it is necessary to convert the features of polymers into numerical values. By applying ECFP (a method for representing monomer structures) to this development work, the researchers found repeating units of molecules (such as functional groups) extracted automatically and structural features expressed appropriately in numerical vectors (Figure 3). Using AI built on these data, the researchers realized high-precision property predictions at the speed of 0.25 second per polymer. Thus, it became possible to make comprehensive property predictions for a large number of candidate polymers within a limited amount of time.

Furthermore, by using Bayesian optimization in prediction, the researchers discovered a polymer with the highest glass transition temperature out of about 400 types of candidate polymers, based on 13.6 sets of training data.

Prior to this study, it was believed that AI-based predictions with a small number of training data would be less accurate, and that a large amount of training data would be required. However, this development work suggests that AI would be effective in solving problems even in the area of developing most-advanced functional materials, where only a limited amount of training data seems to be available.

*[Bayesian optimization: A method for selecting the next candidate material to be examined by considering estimated prediction error, in addition to predicted values.]

We will continue working to improve the technology in order to utilize it in actual development of advanced functional materials. A detailed presentation regarding this development work will be made at 2018 MRS Fall Meeting scheduled for November 27 (U.S. Eastern time).

This development work has been subcontracted by NEDO (New Energy and Industrial Technology Development Organization) Ultra High-Throughput Design and Prototyping Technology for Ultra Advanced Materials Development Project (Ultra-Ultra PJ: P16010). By fully utilizing multiscale simulation and AI, Ultra-Ultra PJ aims to reduce the length of time required for development to one-twentieth compared with conventional ways of material development based on knowledge and experience.

Contact:

SDK

Public Relations Office

Phone: +81-3-5470-3235

Fax: +81-3-3431-6215

AIST

Media Relations Office

Phone: +81-29-862-6216

E-mail: press-ml@aist.go.jp

ADMAT

S. Hatakeyama

Phone: +81-29-856-3580

E-mail: s-hatakeyama@admat.or.jp

Topic: Press release summary

Sectors: Chemicals, Spec.Chem, Materials & Nanotech, Engineering, Automation [IoT]

https://www.acnnewswire.com

From the Asia Corporate News Network

Copyright © 2026 ACN Newswire. All rights reserved. A division of Asia Corporate News Network.

|

|

|

|

|

|

|

| |

Latest Press Releases

Geon Performance Solutions Updates Brand Identity to Reflect Expanded Capabilities in Polymer Industry

Jan 23, 2026 15:16 HKT/SGT

|

|

|

HKTDC and Microsoft Hong Kong jointly launch the Microsoft AI Adoption Programme Helping SMEs boost productivity through AI and accelerate digital transformation

Jan 23, 2026 11:54 HKT/SGT

|

|

|

Davos Highlights Physical AI as Key Trend, 51 WORLD (6651.HK) Emerges as Industry Implementer

Jan 22, 2026 20:13 HKT/SGT

|

|

|

Open World Launches Saudi Arabia's First RWA Tokenization Center of Excellence to Advance Vision 2030 Digital Economy Goals

Jan 22, 2026 20:00 HKT/SGT

|

|

|

The 35th Education & Careers Expo opens today

Jan 22, 2026 18:00 HKT/SGT

|

|

|

Fujitsu and Mizuho Bank partner to develop new order and payment processing service for SMEs

Thursday, January 22, 2026 10:30:00 AM

|

|

|

AmplifiX Releases Comprehensive Sector Report on the Rapid Acceleration of Real-World Asset (RWA) Tokenization

Jan 21, 2026 23:00 HKT/SGT

|

|

|

TANAKA PRECIOUS METAL TECHNOLOGIES to Exhibit Advanced Precious Metal Materials for Medical Device Components at MD&M West 2026

Wednesday, January 21, 2026 9:00:00 PM

|

|

|

Honda to Discontinue Production of Fuel Cell Systems at Fuel Cell System Manufacturing LLC in the U.S.

Wednesday, January 21, 2026 4:44:00 PM

|

|

|

Notice regarding the dissolution of the joint venture in the home elevator business

Wednesday, January 21, 2026 4:04:00 PM

|

|

|

|

|

More Press release >> |

|

|

|