TOKYO, Aug 1, 2024 - (JCN Newswire) - Mitsubishi Heavy Industries Machinery Systems, Ltd. (MHI-MS), a part of Mitsubishi Heavy Industries (MHI) Group, has recently completed development of a three-dimensional variably sized box-making machine "COMPOX" (trademark registration pending) that contributes to reducing delivery costs and improving transportation efficiency for product logistics. MHI-MS will begin accepting orders from September for sales to e-commerce (EC) business operators, and distribution centers that handle packaging and transport.

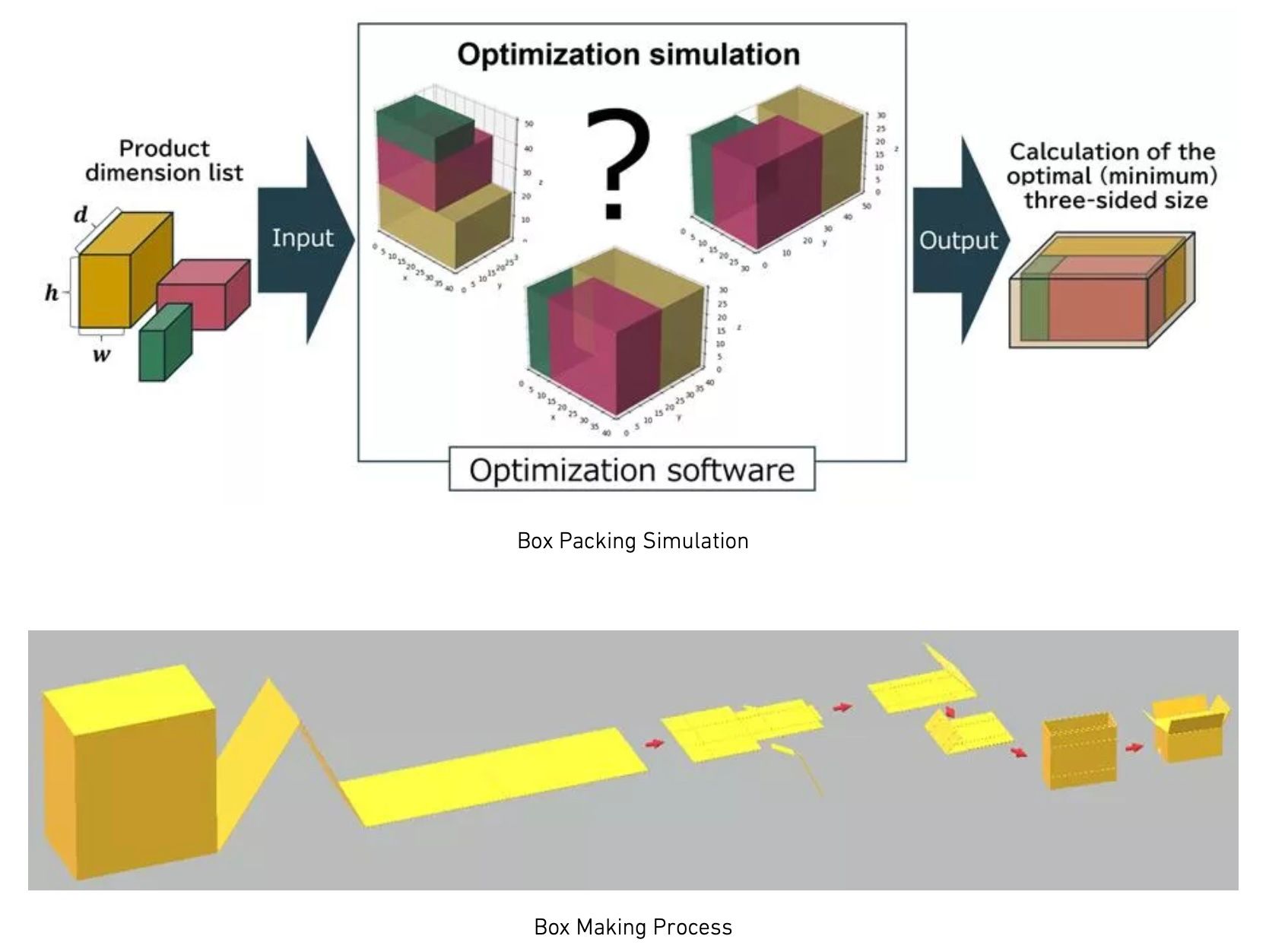

The three-dimensional variably sized box-making machine is packaging process equipment that can automatically adjust the three sides (length, width, and height) of the cardboard box used for shipping products according to the product size, providing a box of the smallest size required for packaging. Cardboard boxes with a total size of all three sides of 50 cm up to a maximum of 130 cm can be automatically produced at a speed of up to 10 boxes per minute (600 boxes per hour). Each box is cut from a continuous feed of corrugated sheets according to the product size and formed into a box, so there is no need to manage materials of multiple sizes. The three-side size is calculated through simulation based on the number of packaged products and size information, using the "Box Size Optimization Software" developed by MHI. In response to the industry's need for manual boxing of liquid packs with unstable shapes, spherical products, and multiple products, standard specifications are applied up to the production of corrugated boxes, and automatic sealing can be added as an option with a separate piece of equipment.

The introduction of this box-making machine will facilitate packing and shipping in the most optimal, smallest box size for the product dimensions, eliminating wasted space and the need for a large amount of cushioning material to fill empty space in the box, which has the potential to contribute significantly to the reduction of delivery costs for e-commerce business operators and distribution centers.(Note) In addition, in response to the regulatory changes in the logistics industry that came into effect in 2024, by automating the entire process from box sizing to box making, this equipment can contribute to reduced workloads and manpower savings, as well as save space on trucks and improve loading efficiency by reducing the size of corrugated boxes, thereby reducing the number of trucks and fuel costs, lowering emissions of CO2 and other greenhouse gases. Further, because of the high degree of design freedom compatible with automated warehouses and digital transformation (DX) strategies, this equipment also offers a new total logistics solution in the form fully automated facility processes from packing to loading.

MHI-MS will continue to apply and integrate the box making technology for paper converting machinery and packaging technology for food machinery that it has cultivated over the years to provide solutions that optimize and improve the efficiency of logistics, and by addressing societal issues such as worker shortages and environmental protection, contribute to the realization of a sustainable world.

Courier service costs are typically determined by the size of the box (the sum of the three sides, the length, width, and height) and the weight. If the weight is fixed, a smaller sum of the three sides is more likely to lower the shipping cost, providing a cost advantage.

About MHI Group

Mitsubishi Heavy Industries (MHI) Group is one of the world’s leading industrial groups, spanning energy, smart infrastructure, industrial machinery, aerospace and defense. MHI Group combines cutting-edge technology with deep experience to deliver innovative, integrated solutions that help to realize a carbon neutral world, improve the quality of life and ensure a safer world. For more information, please visit www.mhi.com or follow our insights and stories on spectra.mhi.com.

Mitsubishi Heavy Industries, Ltd.

Address: 2-3, Marunouchi 3-chome, Chiyoda-ku, Tokyo, 100-8332, Japan

Telephone: 81-3-6275-6200

URL: http://www.mhi.com/

Topic: Press release summary

Source: Mitsubishi Heavy Industries, Ltd.

Sectors: Transport & Logistics, Manufacturing

https://www.acnnewswire.com

From the Asia Corporate News Network

Copyright © 2026 ACN Newswire. All rights reserved. A division of Asia Corporate News Network.

|